High-contact power density

Durability More than 10000Cycles

Easy installation &Replace

High-Current&Low Temperature Rise

Low insertion and withdrawal forces

Low Voltage Drop

High-Vibraton& Mechancial Shock

The High-Performance Spring Contact Socket is a specialized electrical connection component designed to provide stable, repeatable, and reliable contact in applications where precise alignment cannot always be guaranteed. Commonly referred to as a spring socket or spring-loaded contact socket, this product uses an internal spring mechanism to maintain consistent contact force between mating components.

Unlike rigid connectors, spring contact sockets are specifically developed to compensate for tolerance variation, mechanical movement, and repeated mating cycles. At YFS Technology (SZ) Co., Ltd, spring contact sockets are engineered as part of a complete connector solution, focusing on long-term electrical stability, mechanical durability, and adaptability to complex system environments.

These sockets are widely used in applications requiring frequent connection and disconnection, dynamic contact conditions, or limited installation space. By maintaining controlled contact pressure, the spring contact socket ensures dependable signal or power transmission even under vibration, thermal expansion, or mechanical misalignment.

The internal spring structure automatically adjusts contact force during mating, ensuring stable electrical continuity despite dimensional tolerances or movement.

The contact design supports consistent conductivity, helping minimize contact resistance fluctuations during operation.

The spring mechanism absorbs minor alignment errors and dimensional variations, reducing stress on mating components.

The socket is suitable for space-constrained assemblies where traditional connectors may not be practical.

The structure supports frequent insertion cycles without significant degradation of electrical or mechanical performance.

Spring contact sockets are ideal for applications where vibration, shock, or movement could affect rigid connections.

By compensating for tolerance variation, the socket simplifies system design and assembly requirements.

Optimized materials and spring design help maintain consistent performance over extended usage and multiple mating cycles.

Depending on configuration, the socket can be used for signal interfaces, power connections, or mixed applications.

YFS Technology provides application-level support, helping customers integrate spring contact sockets effectively into their connector systems.

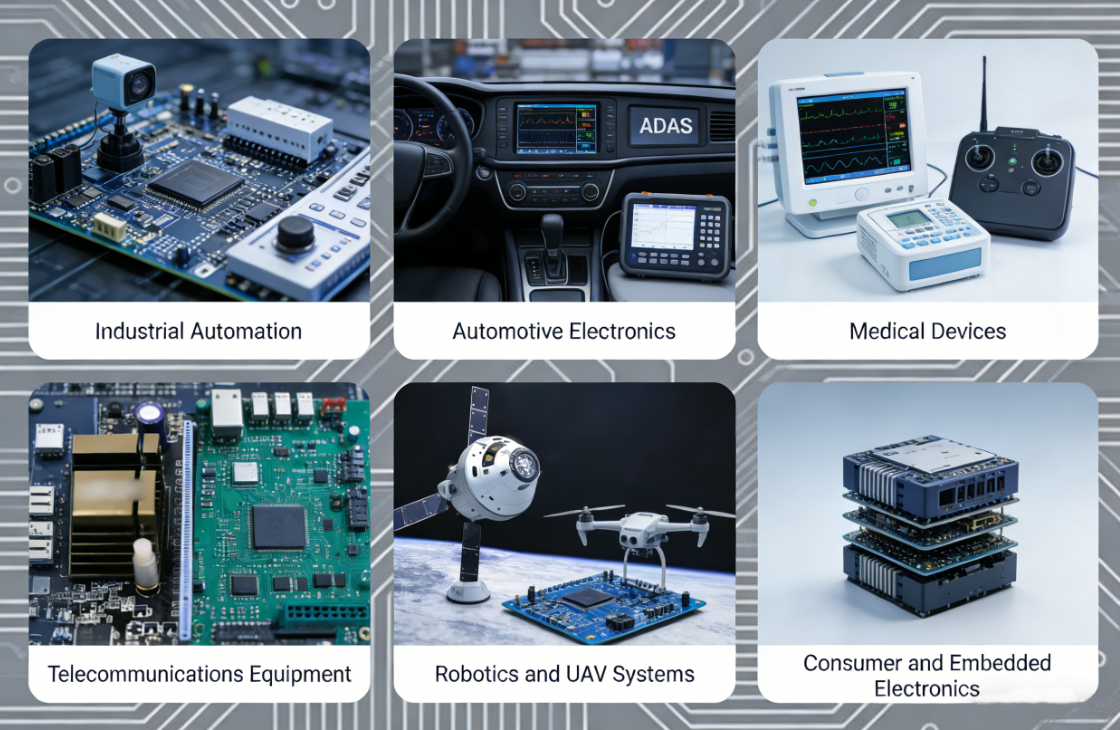

High-Performance Spring Contact Sockets are widely used in applications that require reliable and flexible electrical contact:

Test and measurement equipment

Battery connection and charging interfaces

Industrial automation systems

Consumer electronic docking stations

Automotive electronic modules

Medical electronic devices

Communication equipment and signal interfaces

Board-to-board and module-to-module connections

Q1: What is the main function of a spring contact socket?

A: It provides a stable electrical connection by maintaining constant contact force through an internal spring mechanism.

Q2: Why choose a spring contact socket instead of a rigid connector?

A: Spring contact sockets compensate for alignment and tolerance variations, offering more reliable contact in dynamic or repeated mating applications.

Q3: Are spring contact sockets suitable for frequent connection cycles?

A: Yes. They are designed to withstand repeated insertion and removal while maintaining consistent contact performance.

Q4: Can these sockets handle vibration or movement?

A: Yes. The spring-loaded design helps maintain contact stability under vibration or mechanical movement.

Q5: Does YFS Technology offer customized spring contact socket solutions?

A: Yes. Spring force, contact structure, and dimensional parameters can be customized based on application requirements.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.