Connection sockets represent the critical interface points in electronic systems where components, modules, and peripherals establish both electrical and mechanical relationships. YFS Technology (SZ) Co., Ltd. presents the SocketPro series—a comprehensive family of multi-functional connection sockets engineered to serve as universal interface solutions across diverse electronic applications. These sophisticated socket components provide the essential foundation for component mounting, module interconnection, and peripheral interface requirements, offering standardized yet adaptable connection points for electronic systems ranging from consumer devices to industrial equipment.

The SocketPro series embodies a philosophy of intelligent modularity, where standardized socket designs incorporate flexibility features that accommodate various component types, connection requirements, and system architectures. Unlike single-purpose sockets, our multi-functional designs incorporate adaptable contact arrangements, configurable mounting options, and scalable electrical characteristics that enable a single socket platform to serve multiple roles within an electronic system. This approach provides designers with unprecedented flexibility while maintaining the reliability and performance consistency expected from precision connection components.

In today's rapidly evolving electronics landscape, where system requirements change frequently and time-to-market pressures demand adaptable solutions, SocketPro sockets offer a strategic advantage. By providing standardized interface points that can accommodate various mating components and future upgrades, these sockets enable more flexible system designs, simplified maintenance procedures, and longer product lifecycles through upgradability and component interchangeability.

Modular Contact Architecture

• Interchangeable contact modules for different signal types

• Configurable pin arrangements supporting multiple interface standards

• Mixed signal/power contact configurations within single housing

• Field-replaceable contact elements for maintenance and upgrades

Multi-Standard Compatibility

• Support for various industry-standard connector interfaces

• Adaptable contact spacing and arrangement options

• Configurable polarization and keying features

• Cross-compatibility with multiple component families

Enhanced Reliability Design

• Redundant contact systems for critical connections

• Self-cleaning contact surfaces through wiping action

• Environmental sealing options available

• Vibration-resistant retention mechanisms

Manufacturing Optimization

• Automated assembly compatible designs

• Standardized footprints for simplified PCB layout

• Visual alignment and orientation features

• Bulk, tape, or tray packaging options

Design Flexibility and Future-Proofing

SocketPro sockets provide designers with a platform approach to system connectivity. By standardizing on a versatile socket platform, engineers can accommodate current component requirements while maintaining the flexibility to incorporate future technologies or alternative components without redesigning the core system architecture.

Reduced Inventory Complexity

A single SocketPro socket type can replace multiple specialized sockets in inventory, simplifying procurement, reducing storage requirements, and minimizing the risk of using incorrect components in assembly. This consolidation provides significant cost savings through reduced SKU management and inventory carrying costs.

Improved Serviceability and Maintenance

Field-replaceable contact elements and modular construction enable simpler maintenance procedures and faster repair turnaround times. Technicians can replace individual contacts or modules without replacing entire sockets, reducing service costs and minimizing system downtime.

Enhanced System Reliability

Through standardized, proven designs and consistent manufacturing quality, SocketPro sockets deliver reliable performance across diverse applications. The modular approach allows optimization of contact types for specific signal requirements while maintaining consistent mechanical and environmental performance.

Streamlined Manufacturing Processes

Standardized socket designs simplify assembly procedures, reduce training requirements, and improve manufacturing yields. Consistent mechanical and electrical characteristics ensure predictable performance in automated assembly environments, reducing variability and improving quality control.

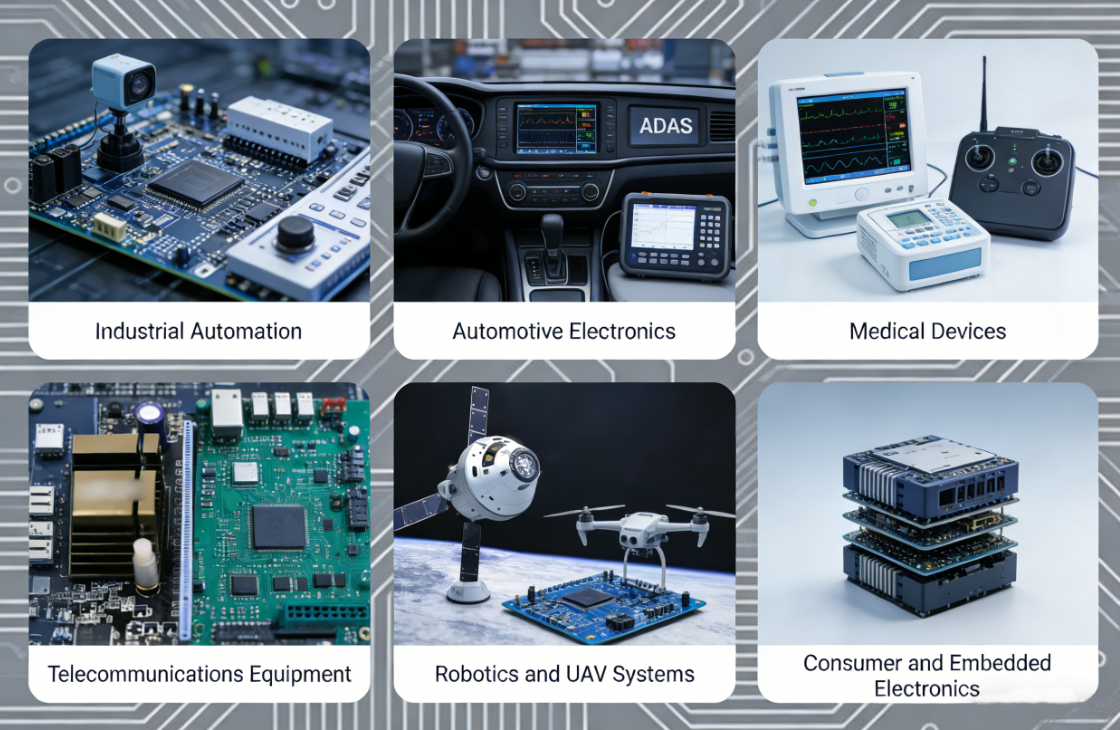

Industrial Control Systems

• PLC module interface sockets

• Industrial computer expansion slots

• Sensor and actuator interface points

• Control panel component mounting

Telecommunications Equipment

• Network card interface sockets

• Line card connection points

• Module expansion interfaces

• Service and maintenance ports

Medical Electronic Systems

• Modular diagnostic equipment interfaces

• Sensor and probe connection points

• Display and control module mounting

• Service and calibration access points

Consumer Electronics

• Smart device accessory interfaces

• Charging and data connection sockets

• Component upgrade and repair points

• Peripheral device connections

Automotive Electronics

• Control module interface sockets

• Sensor connection points

• Display and infotainment interfaces

• Diagnostic and service access points

Test and Measurement Equipment

• Instrument module interface sockets

• Probe and accessory connection points

• Calibration and service interfaces

• Expansion and upgrade slots

Data Center Equipment

• Server expansion card sockets

• Storage device interfaces

• Network module connections

• Power and management interfaces

Q: What types of contacts can SocketPro sockets accommodate?

A: SocketPro sockets can accommodate various contact types including signal contacts for low-level signals, power contacts for current carrying, coaxial contacts for RF signals, and fiber optic interfaces. The modular design allows mixing different contact types within the same socket housing to meet specific application requirements.

Q: How does the modular contact system work?

A: The modular system uses standardized contact modules that insert into the socket housing. Each module contains one or more contacts of a specific type. Modules can be combined in different configurations to create custom socket arrangements. Modules are secured with retention features that ensure proper alignment and electrical connection.

Q: Can SocketPro sockets be customized for specific applications?

A: While SocketPro sockets offer extensive configuration options through modular components, we also provide custom design services for applications with unique requirements. Customization can include specialized housing materials, unique contact arrangements, environmental sealing features, or specific mounting configurations.

Q: What is the typical mating cycle life?

A: Standard SocketPro sockets are rated for 10,000 mating cycles for signal contacts and 5,000 cycles for power contacts. High-cycle versions are available for applications requiring more frequent connections. Actual cycle life depends on contact type, environmental conditions, and maintenance practices.

Q: How are different contact types identified in mixed configurations?

A: We provide multiple identification methods including color-coded contact modules, keyed housing features, labeling options, and documentation support. For critical applications, we can implement positive polarization features that prevent incorrect module installation.

Q: What environmental protection levels are available?

A: Standard sockets provide basic environmental protection. Sealed versions with IP67 or higher ratings are available for harsh environment applications. Additional protection options include corrosion-resistant materials, UV-stable housings, and specialized sealing for specific environmental challenges.

Q: How does the field replacement system work?

A: Field replacement uses simple tools to remove and install contact modules without disassembling the entire socket. Replacement modules include all necessary contacts and retention features. The system is designed for service by trained technicians using standard hand tools.

Q: What documentation and support is provided for configuration?

A: We provide comprehensive configuration guides, technical specifications for all modular components, application notes for common configurations, and design support from our application engineering team. Online configuration tools and technical support are available to assist with specific application requirements.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.