Current: Rated current 300A

Max Mated Pin: T=2*18mm

Mated Axial:90°C、180°C

Durability:5000cycles

Can be customized according to customer defined

The rectangular socket connector is a versatile interconnection component designed to support stable signal and power transmission in modular electronic systems. Featuring a standardized rectangular interface, this connector enables precise alignment, high contact integrity, and flexible mating with corresponding pin or blade connectors.

As part of YFS Technology’s connector solution portfolio, this rectangular socket connector is engineered to meet the growing demand for compact layouts, scalable system design, and long-term reliability across industrial electronics, communication equipment, automotive modules, and smart devices.

Compared with round or spring-loaded interfaces, rectangular socket connectors provide higher layout efficiency, clearer pin orientation, and stronger mechanical stability, making them ideal for applications where repeatable assembly and secure electrical contact are critical.

Rectangular Contact Geometry

Ensures accurate positioning and consistent mating force, reducing the risk of misalignment during assembly.

High-Density Pin Arrangement

Supports multi-circuit integration within limited PCB space, ideal for compact electronic designs.

Precision Metal Contacts

Manufactured from copper alloy with optional gold or tin plating to ensure low contact resistance and stable conductivity.

Insulated Housing Design

High-performance thermoplastic materials provide excellent electrical insulation, heat resistance, and structural strength.

Compatibility with Automated Assembly

Designed for wave soldering or reflow soldering processes, suitable for mass production environments.

Rectangular socket connectors provide a large and uniform contact surface, minimizing signal loss and ensuring stable current flow even in high-frequency or vibration-prone environments.

The rectangular structure allows connectors to be arranged closely in parallel, helping engineers maximize PCB density without sacrificing reliability.

The locking and guiding structure improves insertion accuracy and retention force, reducing accidental disconnection during operation or transport.

Pin count, pitch, plating thickness, housing material, and mounting type can be customized to match different application requirements.

Designed to withstand repeated mating cycles, thermal variation, and environmental stress, supporting long-term system operation.

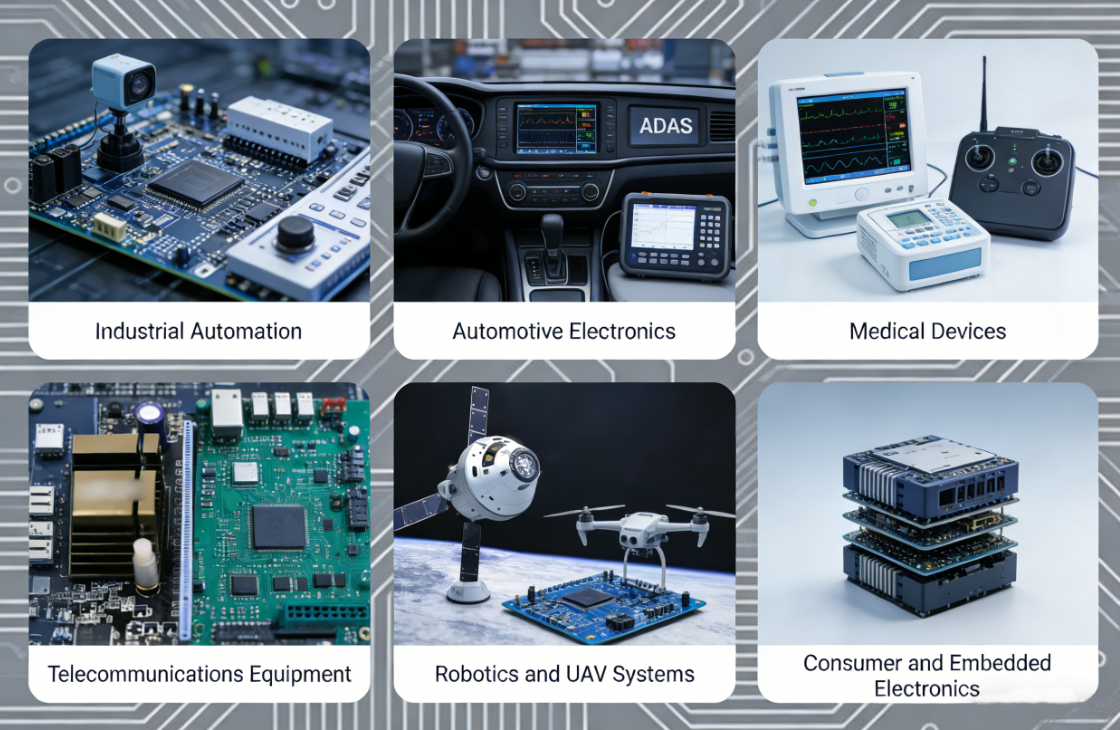

Used in PLC modules, control boards, and automation equipment where stable multi-signal connections are required.

Applied in dashboard modules, control units, power distribution systems, and vehicle communication interfaces.

Ideal for routers, base stations, signal processing units, and data transmission modules requiring compact and reliable connectors.

Commonly used in smart devices, docking stations, display modules, and power management boards.

Supports precise signal transmission in diagnostic equipment, monitoring systems, and portable medical electronics.

Q1: What is the main difference between a rectangular socket connector and a round socket?

Rectangular socket connectors offer better space efficiency, clearer orientation, and stronger mechanical stability, making them more suitable for high-density and modular designs.

Q2: Can rectangular socket connectors handle both signal and power transmission?

Yes. Depending on contact size and material, they can support low-current signals as well as moderate power transmission.

Q3: Are these connectors suitable for high-vibration environments?

Yes. The rectangular structure and secure contact design help maintain stable connections in automotive and industrial applications.

Q4: Can the connector be customized for specific projects?

Absolutely. Pin layout, pitch, housing material, and surface plating can be tailored to meet different technical requirements.

Q5: Do rectangular socket connectors support automated assembly?

Yes. They are designed to be compatible with automated soldering and assembly processes.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.