In the realm of precision testing and high-reliability connections, spring-loaded probe systems have become indispensable for establishing temporary yet robust electrical interfaces. YFS Technology (SZ) Co., Ltd. introduces the PogoProbe series—a specialized category of spring-loaded contact probes designed for applications requiring consistent electrical performance across thousands of connection cycles while accommodating mechanical variations. These precision components are engineered to bridge the gap between test equipment and device under test, or between modular electronic assemblies where reliable but separable connections are essential.

PogoProbe technology addresses a critical need in modern electronics manufacturing and testing: establishing reliable electrical contact without the permanence or potential damage of soldered connections. Each probe functions as a miniature spring mechanism that maintains optimal contact force against mating surfaces, compensating for surface irregularities, minor misalignments, and thermal expansion effects. This adaptive capability makes them ideal for applications ranging from semiconductor testing and PCB validation to modular equipment interfaces and charging connections in portable devices.

Our engineering approach recognizes that successful spring probe applications require precise balance between mechanical force, electrical performance, and durability. The PogoProbe series represents this balance through meticulous design of spring characteristics, contact geometry, plating systems, and housing configurations. These components are not merely electrical contacts but engineered solutions that ensure reliable signal integrity and power delivery in applications where connection consistency directly impacts testing accuracy or system performance.

Precision Spring Mechanics

Calibrated spring forces ranging from 50g to 500g per probe

Consistent force-deflection characteristics for predictable performance

Anti-overcompression features preventing spring damage

Custom spring rates available for specific application requirements

Advanced Contact Design

Multi-finger crown contacts for reliable surface connection

Self-cleaning action through wiping motion during actuation

Plated contact surfaces (gold, nickel, rhodium options)

Optimized tip geometries for specific surface types

Electrical Performance Characteristics

Low contact resistance (<30mΩ typical)

Current carrying capacity up to 3A per probe

High-frequency optimized versions available

Stable electrical characteristics across temperature range

Durability & Reliability

Cycle life ratings from 50,000 to 1,000,000 actuations

Corrosion-resistant materials for harsh environments

Temperature range: -40°C to +125°C operation

Vibration and shock resistant designs

Consistent Electrical Performance

PogoProbe spring contacts maintain stable contact resistance and reliable signal transmission across thousands of mating cycles. The precisely controlled spring force ensures optimal contact pressure against mating surfaces, minimizing contact resistance variation and ensuring accurate measurements in testing applications or reliable connections in modular systems.

Accommodation of Mechanical Variations

The spring-loaded design naturally compensates for surface irregularities, minor misalignments, and dimensional variations between mating surfaces. This tolerance accommodation capability reduces the need for precision alignment fixtures and simplifies assembly processes in production environments, improving manufacturing yield and reducing assembly costs.

High-Cycle Reliability

Engineered for applications requiring frequent connection and disconnection, PogoProbe components offer extended service life compared to traditional contact methods. The optimized contact geometry and durable materials minimize wear during repeated actuation, maintaining performance characteristics throughout the rated lifecycle and reducing maintenance requirements.

Application-Specific Optimization

With multiple tip geometries, spring force options, and plating choices, PogoProbe contacts can be optimized for specific applications. Whether requiring minimal penetration force for delicate surfaces, high current capacity for power connections, or specialized tip shapes for specific contact patterns, our engineering team can recommend or develop optimal configurations for unique requirements.

Enhanced Testing Accuracy

In test and measurement applications, the consistent performance of PogoProbe contacts translates directly to improved measurement accuracy and repeatability. Stable contact resistance minimizes measurement errors, while reliable mechanical actuation ensures consistent test conditions across multiple test cycles and device samples.

Semiconductor Testing

IC test sockets and carriers

Wafer probe card contacts

Package-level test interfaces

Burn-in and reliability testing fixtures

PCB Testing & Validation

Flying probe test systems

In-circuit test fixtures

Functional test interfaces

Boundary scan test points

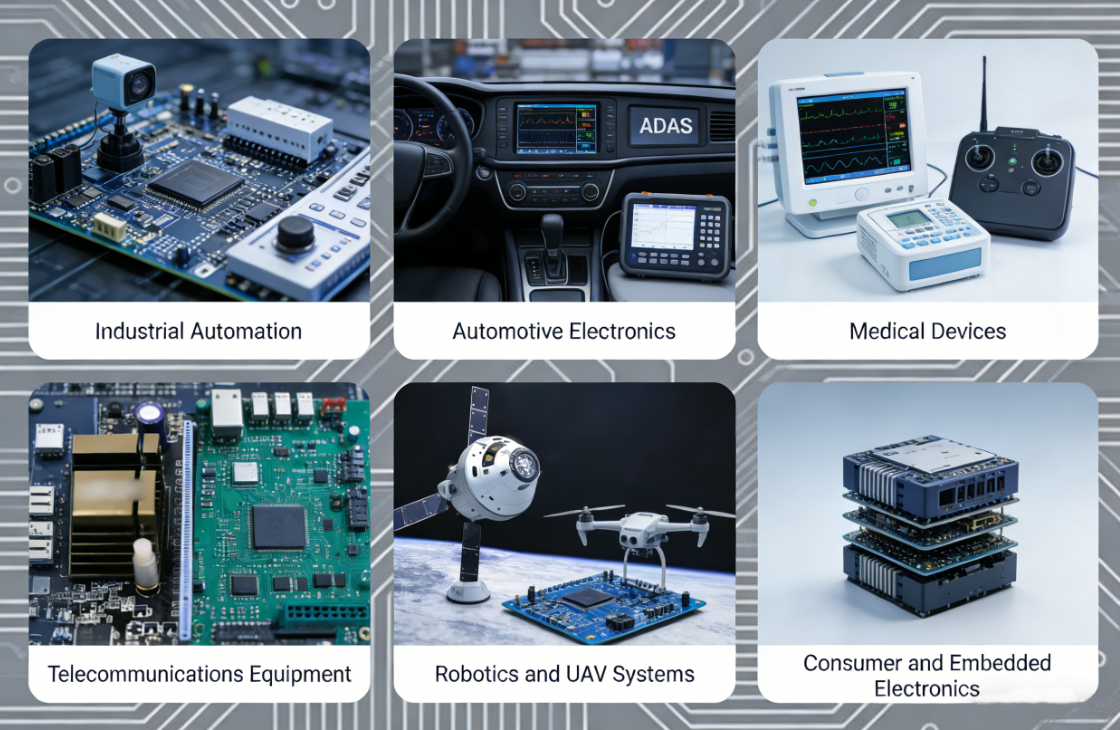

Consumer Electronics

Portable device charging contacts

Smartwatch and wearable connections

Modular smartphone component interfaces

Gaming controller charging systems

Medical Devices

Diagnostic equipment test points

Portable medical device charging

Patient monitoring connections

Disposable sensor interfaces

Industrial Automation

Control system test interfaces

Sensor calibration connections

Equipment maintenance ports

Modular I/O system connections

Automotive Electronics

ECU programming and test ports

Sensor calibration interfaces

Infotainment system connections

Diagnostic equipment interfaces

Telecommunications

Network equipment test points

Base station maintenance ports

Fiber optic equipment interfaces

Test equipment calibration standards

Q: What is the typical lifespan of PogoProbe contacts?

A: Standard PogoProbe contacts are rated for 50,000 to 100,000 actuation cycles while maintaining electrical specifications. High-cycle versions are available for up to 1,000,000 cycles. Actual lifespan depends on operating conditions including contact force, environmental factors, and mating surface characteristics.

Q: How do I select the appropriate spring force for my application?

A: Spring force selection depends on several factors: contact surface hardness, required contact resistance, mating surface condition, and application environment. Lighter forces (50-150g) are suitable for delicate surfaces, while heavier forces (200-500g) provide better contact reliability on oxidized or contaminated surfaces. Our application engineering team can recommend optimal force based on your specific requirements.

Q: Can PogoProbe contacts handle high-frequency signals?

A: Yes, we offer specialized high-frequency PogoProbe versions with controlled impedance characteristics, optimized signal path geometry, and minimized parasitic effects. These versions are suitable for testing RF components, high-speed digital interfaces, and other applications requiring signal integrity at frequencies up to several GHz.

Q: What plating options are available and how do they affect performance?

A: Standard plating options include: gold over nickel for excellent conductivity and corrosion resistance, rhodium for extreme hardness and wear resistance, and nickel for cost-effective general applications. Plating selection affects contact resistance, durability, and compatibility with different mating surface materials. Specialized platings are available for unique application requirements.

Q: How does tip geometry affect performance?

A: Tip geometry significantly impacts contact reliability. Crown tips provide multiple contact points for reliable connection on irregular surfaces. Pointed tips offer better penetration of oxide layers but may cause surface damage. Serrated tips combine penetration capability with multiple contact points. The optimal tip geometry depends on mating surface characteristics and application requirements.

Q: What maintenance is required for PogoProbe contacts?

A: Recommended maintenance includes periodic cleaning of contact surfaces to remove oxidation and contamination, inspection for wear or damage, and verification of contact resistance. Some applications benefit from occasional lubrication of sliding surfaces. Maintenance frequency depends on usage conditions and performance requirements.

Q: Can custom configurations be developed for unique applications?

A: Yes, we offer comprehensive custom design services for PogoProbe contacts with specific dimensions, force requirements, electrical characteristics, or performance specifications not available in standard products. Custom development typically involves requirements analysis, prototype development, testing validation, and production ramp-up.

Q: How are PogoProbe contacts tested for quality assurance?

A: Quality testing includes dimensional verification, spring force measurement, contact resistance testing, cycle life testing, environmental testing, and functional validation in simulated application conditions. Statistical process control monitors production parameters, and comprehensive documentation ensures traceability and quality consistency.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.