In the realm of electronic interconnection where reliability, durability, and consistent electrical performance are paramount, spring-loaded contact sockets represent a sophisticated engineering solution for demanding applications. YFS Technology (SZ) Co., Ltd. introduces the SpringSocket series—a comprehensive range of precision-engineered spring contact sockets designed to deliver exceptional performance in applications requiring frequent mating cycles, vibration resistance, thermal cycling endurance, and stable electrical characteristics. These components provide the critical interface between electronic modules, test points, and mating connectors where traditional fixed-contact solutions prove inadequate for modern reliability requirements.

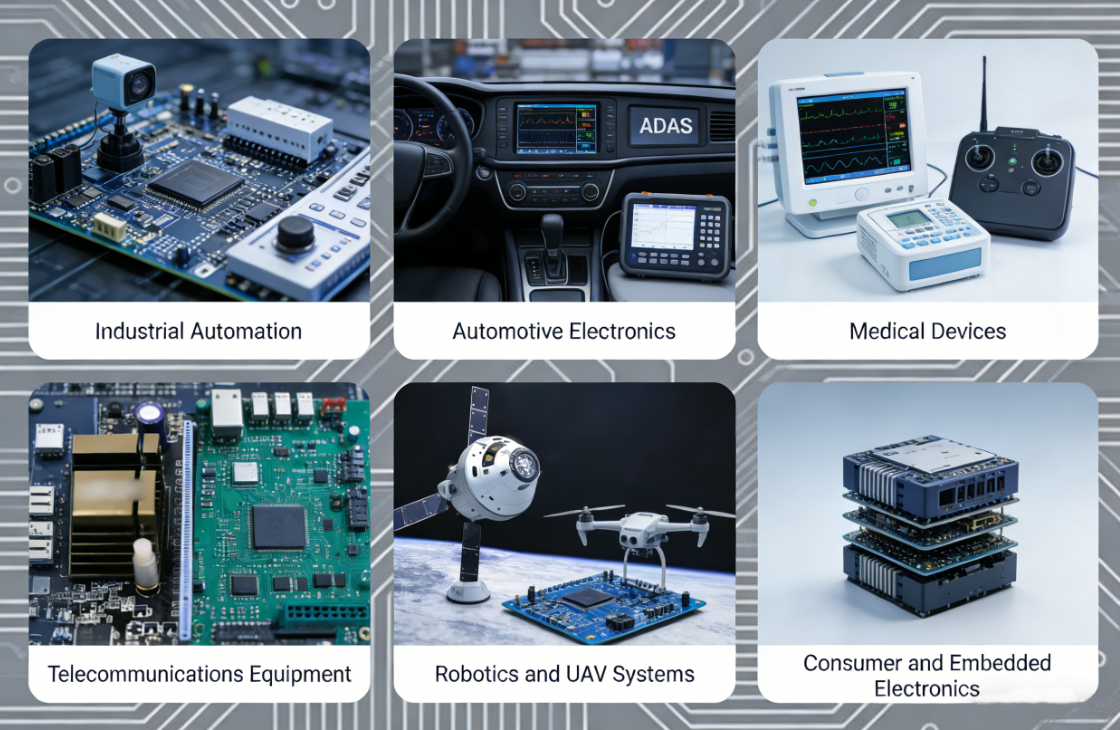

SpringSocket technology addresses the fundamental challenge of maintaining consistent electrical contact under real-world operating conditions where mechanical movement, thermal expansion, and environmental factors can compromise connection integrity. Unlike rigid pin-and-socket arrangements, our spring-loaded sockets incorporate precisely calibrated spring mechanisms that maintain optimal contact force throughout the product lifecycle, accommodating manufacturing tolerances, compensating for thermal expansion differentials, and resisting vibration-induced disconnection. This intelligent approach to contact design has established spring sockets as the preferred solution in applications ranging from industrial automation and telecommunications infrastructure to automotive electronics and medical equipment.

Our engineering philosophy recognizes that successful interconnection in demanding environments requires more than just conductive materials—it demands a systems approach that integrates mechanical reliability with electrical performance. The SpringSocket series embodies this approach through meticulous design, advanced materials selection, and rigorous testing protocols that ensure predictable performance across millions of mating cycles and under the most challenging environmental conditions.

Advanced Spring Mechanism Design

Multi-finger beryllium copper spring designs providing consistent normal force

Precision-formed contact geometries for reliable electrical interface

Optimized spring rates for specific application force requirements

Dual-spring configurations for redundant contact assurance

Superior Electrical Performance

Low and stable contact resistance (<10mΩ typical)

High-current carrying capacity options (up to 30A per contact)

RF-optimized designs with controlled impedance characteristics

Plating systems optimized for specific contact resistance requirements

Environmental Durability

Operating temperature range: -65°C to +150°C

Corrosion-resistant plating systems (gold, nickel, specialized coatings)

Sealed versions available for harsh environment applications

Vibration resistance exceeding 20G (10-2000Hz)

Mechanical Reliability

Mating cycle life exceeding 100,000 cycles

Wear-resistant contact surfaces with specialized platings

Positive latching mechanisms for secure connection

Anti-overstress features preventing spring damage during mating

Consistent Performance Under Variable Conditions

The spring-loaded design of YFS SpringSocket components ensures maintained contact force even when faced with vibration, shock, thermal expansion, or minor misalignment. This consistency translates directly to reliable signal transmission and power delivery in applications where traditional fixed contacts might fail due to environmental stresses or mechanical movement.

Extended Service Life and Reduced Maintenance

With mating cycle ratings significantly exceeding standard connector solutions, SpringSocket components reduce maintenance requirements and increase system uptime. The wear-resistant materials and optimized contact geometries minimize degradation over time, extending the service interval between replacements and reducing total cost of ownership.

Enhanced Design Flexibility

Spring-loaded sockets accommodate a range of mating pin diameters and tolerances, providing designers with greater flexibility in mating component selection. This tolerance compensation capability simplifies assembly processes, reduces manufacturing costs associated with tight tolerances, and improves overall system manufacturability.

Improved Electrical Reliability

The multi-point contact design and consistent spring force ensure stable electrical characteristics throughout the product lifecycle. This reliability is critical in applications where connection integrity directly impacts system safety, performance, or regulatory compliance, such as in medical devices, automotive safety systems, and industrial controls.

Comprehensive Application Support

YFS provides extensive technical support including spring force optimization for specific applications, custom contact plating recommendations, mating interface design guidance, and environmental compatibility analysis to ensure successful implementation in challenging operating conditions.

Industrial Automation Systems

PLC and controller module connections

Industrial sensor interfaces in high-vibration environments

Robotic arm control and power connections

Manufacturing equipment safety interlock systems

Telecommunications Infrastructure

Base station equipment module connections

Network switch and router hot-swappable modules

Data center server backplane connections

Outdoor telecommunications equipment interfaces

Automotive Electronics

Engine control unit connections under hood conditions

Transmission and braking system electronic interfaces

Electric vehicle battery management system connections

Advanced driver assistance system sensor interfaces

Medical Equipment

Diagnostic imaging equipment modular connections

Patient monitoring system disposable/reusable interfaces

Surgical equipment power and data connections

Portable medical device charging and data ports

Test and Measurement Equipment

Automated test equipment interface connections

Semiconductor test socket contacts

Laboratory instrument calibration interfaces

Production line testing fixtures

Aerospace and Defense Systems

Avionics equipment modular connections

Military communications equipment interfaces

Satellite system electronic module connections

Ground support equipment test interfaces

Q: What spring force ranges are available for different applications?

A: YFS SpringSocket components are available with spring forces ranging from 50g to 500g per contact, with specialized designs available outside this range. Lower forces are suitable for delicate contacts and frequent mating cycles, while higher forces provide better vibration resistance and current carrying capacity. Our engineering team can recommend optimal force specifications based on your specific application requirements.

Q: How does contact plating affect performance in spring sockets?

A: Contact plating significantly impacts electrical performance, durability, and environmental resistance. Gold plating provides excellent conductivity and corrosion resistance but at higher cost. Nickel plating offers good wear resistance and serves as an effective barrier layer. Rhodium provides extreme hardness for high-wear applications. The optimal plating combination depends on mating cycles, environmental conditions, current requirements, and budget considerations.

Q: What is the expected contact resistance stability over the product lifecycle?

A: YFS SpringSocket components are designed to maintain contact resistance within ±20% of initial values throughout their rated service life. This stability is achieved through optimized contact geometries, carefully selected plating systems, and consistent spring force characteristics. Extended testing under accelerated life conditions confirms this performance characteristic across our product range.

Q: Can spring sockets accommodate different mating pin geometries?

A: Yes, our spring socket designs can be optimized for specific pin geometries including round pins, square pins, blade contacts, and custom shapes. The contact spring geometry is engineered to provide optimal contact points for the specific mating interface while maintaining consistent spring force and electrical characteristics.

Q: How are spring sockets tested for reliability?

A: Reliability testing includes: accelerated life testing with continuous mating cycles, thermal cycling between extreme temperatures, vibration and shock testing per industry standards, mixed flowing gas testing for corrosion resistance, and current cycling tests to verify thermal performance. Testing protocols are tailored to specific application requirements and industry standards.

Q: What customization options are available?

A: Customization possibilities include: specific spring force requirements, custom contact plating combinations, specialized housing materials, unique mounting configurations, integrated sealing for environmental protection, and custom electrical configurations. Our engineering team works closely with customers to develop optimized solutions for unique application challenges.

Q: How does temperature affect spring socket performance?

A: Temperature variations affect spring force characteristics, contact resistance, and material properties. YFS SpringSocket components are designed with temperature-compensated spring materials and plating systems that maintain performance across the specified operating range. For extreme temperature applications, specialized materials and designs are available to ensure reliable operation.

Q: What quality assurance processes are implemented?

A: Our quality management system includes: 100% electrical testing of all contacts, statistical process control for critical dimensions, batch testing for mechanical and environmental performance, material certification traceability, and comprehensive documentation of all production parameters. We maintain compliance with relevant industry standards including ISO 9001 and industry-specific quality requirements.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.