Electronic interconnection pins serve as the fundamental bridge components in modern electrical systems, providing the essential conductive pathways that enable reliable signal transmission, power distribution, and mechanical support across diverse applications. YFS Technology (SZ) Co., Ltd. presents the InterconnectPin series—a comprehensive range of precision-engineered electronic pins and posts designed to address the sophisticated connectivity requirements of today's electronics industry. These components represent more than simple conductive elements; they are engineered solutions that balance electrical performance, mechanical reliability, thermal management, and manufacturing efficiency in increasingly complex electronic assemblies.

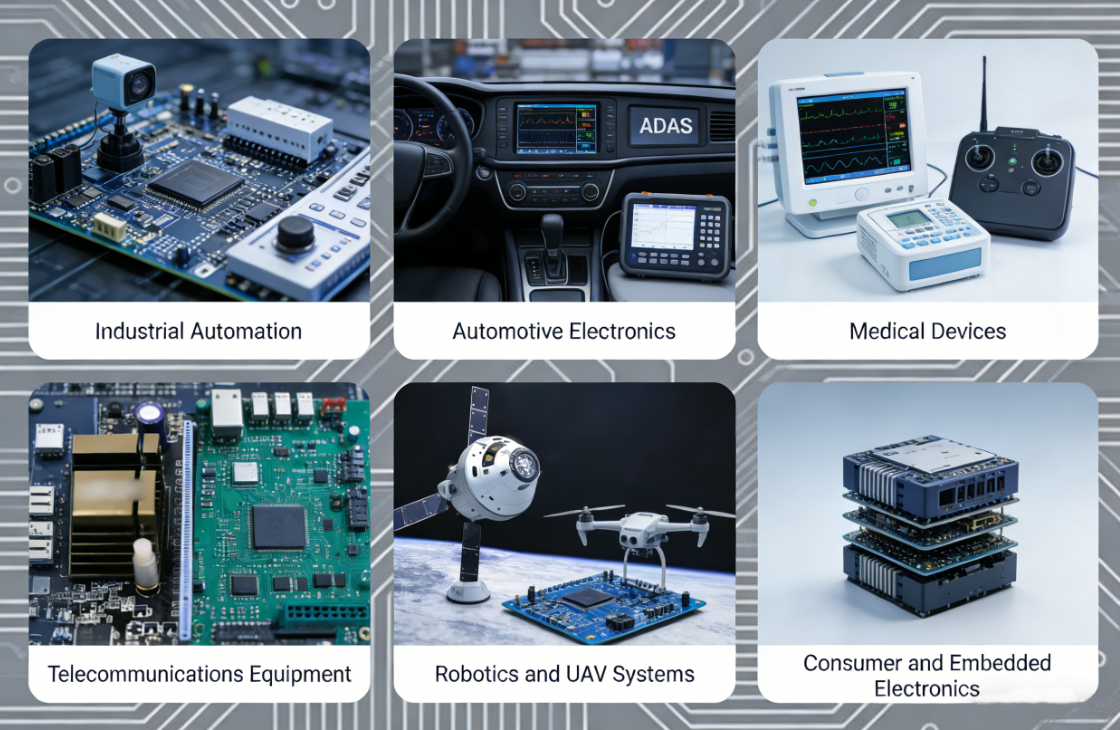

In an era where electronic devices are becoming simultaneously more compact and more powerful, the role of interconnection pins has evolved significantly. No longer merely passive components, modern pins must maintain signal integrity at higher frequencies, support greater current loads in smaller packages, withstand more demanding environmental conditions, and enable increasingly automated manufacturing processes. YFS InterconnectPin solutions are engineered with these advanced requirements in mind, offering performance-optimized designs that support the next generation of electronic innovation across consumer, industrial, automotive, medical, and telecommunications applications.

Advanced Material Engineering

Multiple copper alloy options including phosphor bronze, beryllium copper, and brass for specific application requirements

Specialized plating systems: selective gold plating, tin-lead alternatives, nickel barriers, and precious metal finishes

High-temperature resistant materials for reflow and wave soldering processes

RoHS 3 compliant and halogen-free material options available

Precision Manufacturing Capabilities

Diameter tolerances as tight as ±0.005mm for critical applications

Consistent plating thickness control across entire pin surface

Advanced machining for complex geometries and custom head designs

100% automated optical inspection for dimensional accuracy verification

Electrical Performance Optimization

Low contact resistance designs with optimized surface finishes

High-frequency compatible geometries for RF and high-speed digital applications

Current-carrying capacity optimization through material selection and cross-sectional design

EMI/RFI shielding capabilities in specialized configurations

Mechanical Reliability Features

Enhanced fatigue resistance for high-cycle applications

Optimized insertion force profiles for manual and automated assembly

Corrosion-resistant finishes for harsh environment applications

Temperature cycling performance exceeding industry standards

Superior Electrical Performance

YFS InterconnectPin components are engineered to minimize signal loss and maximize power transfer efficiency. Through careful control of material properties, surface finishes, and geometric design, our pins provide consistently low contact resistance and excellent signal integrity across a wide range of operating conditions. This translates to improved system performance, reduced power losses, and enhanced reliability in critical applications.

Enhanced Manufacturing Efficiency

The precision manufacturing of InterconnectPin components ensures consistent quality and dimensional accuracy, enabling high-yield automated assembly processes. Our pins are designed with manufacturability in mind, featuring geometries that facilitate reliable feeding, orientation, and placement in high-speed production equipment. This reduces assembly time, minimizes rework, and improves overall production efficiency.

Application-Specific Optimization

Unlike generic pin solutions, YFS offers application-optimized designs for specific use cases. Whether the requirement is for high-current power distribution, high-frequency signal transmission, harsh environment durability, or ultra-miniaturization, our engineering team can recommend or develop pin solutions that precisely match the application requirements while maintaining cost-effectiveness.

Comprehensive Quality Assurance

Every batch of InterconnectPin components undergoes rigorous quality testing including dimensional verification, plating thickness measurement, mechanical property testing, and sample electrical testing. Our commitment to quality extends throughout the supply chain, from raw material selection through final packaging, ensuring consistent performance and reliability.

Technical Partnership Approach

YFS positions itself as a technical partner rather than just a component supplier. We provide comprehensive design support, application engineering assistance, prototyping services, and manufacturing process recommendations to help customers optimize their designs and production processes around our pin solutions.

High-Density Consumer Electronics

Smartphone antenna connections and battery interfaces

Tablet computer board-to-board interconnections

Wearable device charging and data ports

Smart home device internal connections

Industrial Automation Systems

PLC backplane connection pins

Industrial sensor interface connections

Motor control power distribution pins

Factory automation equipment interconnects

Automotive Electrical Systems

Electric vehicle battery management connections

Advanced driver assistance system sensor interfaces

Infotainment system board interconnects

Lighting control module connections

Medical Equipment Manufacturing

Diagnostic imaging equipment internal connections

Patient monitoring system interfaces

Portable medical device battery and data connections

Surgical instrument control connections

Telecommunications Infrastructure

5G base station equipment interconnections

Network switch and router backplane pins

Data center server power distribution

Fiber optic network equipment electrical interfaces

Power Electronics Applications

Solar inverter power connections

UPS system battery interface pins

Power supply module interconnections

Industrial motor drive connections

Q: What is the difference between stamped and machined pins?

A: Stamped pins are produced through progressive die stamping processes and are typically more cost-effective for high-volume applications with simpler geometries. Machined pins are produced through CNC turning or milling and offer greater design flexibility, tighter tolerances, and the ability to create more complex geometries. The choice depends on volume requirements, design complexity, and budget considerations.

Q: How does pin plating thickness affect performance?

A: Plating thickness directly impacts several performance aspects: Thicker gold plating provides better wear resistance for high-cycle applications, improved corrosion resistance, and lower contact resistance. However, it increases cost. Thinner platings are more cost-effective but may wear through more quickly. The optimal thickness depends on the specific application requirements including mating cycles, environmental conditions, and current requirements.

Q: What are the considerations for high-frequency pin design?

A: High-frequency pin design requires attention to several factors: controlled impedance along the pin length, minimized parasitic capacitance and inductance, consistent dielectric properties, and proper grounding strategies. Specialized geometries and materials may be required to maintain signal integrity at microwave frequencies.

Q: How are pins tested for mechanical durability?

A: Mechanical testing typically includes: insertion/withdrawal force measurement, bending strength testing, fatigue testing through repeated deflection cycles, and pull-out force testing from mounted positions. Environmental stress testing including thermal cycling, vibration, and shock testing may also be performed based on application requirements.

Q: Can pins be supplied with custom packaging?

A: Yes, we offer a range of packaging options including custom reel sizes for automated assembly, special tube packaging for specific insertion equipment, bulk packaging with custom quantities, and specialized packaging for ESD-sensitive applications. Custom labeling, barcoding, and tracking systems can also be implemented.

Q: What lead times are available for standard and custom pins?

A: Standard pin configurations are typically available from stock or with short lead times of 2-4 weeks. Custom designs require development time that varies based on complexity but typically range from 6-12 weeks for initial samples followed by production ramp-up. Expedited services are available for urgent requirements.

Q: How does material selection affect pin performance?

A: Material selection impacts multiple performance aspects: Copper alloys offer different balances of conductivity, strength, and spring properties; plating materials affect contact resistance, wear characteristics, and corrosion resistance; base material temper affects formability and mechanical strength. Our engineering team can recommend optimal material combinations for specific applications.

Q: What documentation and certifications are provided?

A: We provide comprehensive documentation including material certifications, plating thickness reports, dimensional inspection reports, RoHS compliance certificates, and when applicable, industry-specific certifications (automotive, medical, aerospace). All documentation is maintained in our quality management system and available to customers.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.