Electronic connection pins represent the fundamental building blocks of modern electrical connectivity, serving as the critical interface points that enable reliable signal transmission and power distribution across countless electronic applications. YFS Technology (SZ) Co., Ltd. introduces the PrecisionPin series—a comprehensive portfolio of precision-engineered electronic pins designed to meet the exacting demands of contemporary electronics manufacturing. These components form the essential foundation for board-to-board connections, component mounting, test point interfaces, and modular system architectures where consistent performance and reliable connectivity are non-negotiable.

In today's rapidly evolving electronics landscape, where devices continue to shrink in size while expanding in functionality, the humble connection pin has evolved from a simple conductive element into a sophisticated engineering component. YFS PrecisionPin solutions address this evolution through meticulous design considerations that balance electrical performance, mechanical durability, and manufacturability. Our pins serve as the critical link between semiconductors, printed circuit boards, connectors, and external interfaces—a role that demands uncompromising precision and reliability across diverse operating environments and application scenarios.

Material Excellence

High-conductivity copper alloys (CDA 101, 102, 110) with optimized temper characteristics

Advanced plating systems including selective gold, tin, nickel, and silver finishes

Specialized surface treatments for enhanced solderability and corrosion resistance

RoHS-compliant materials meeting international environmental standards

Precision Manufacturing

Diameter tolerances maintained within ±0.01mm for consistent fit and performance

Length precision ensuring uniform board standoff and component alignment

Straightness specifications guaranteeing reliable insertion and mating

Advanced plating thickness control for optimal electrical and mechanical properties

Design Versatility

Multiple head styles including flat, domed, tapered, and custom profiles

Various termination options: solder tail, press-fit, compliant pin, and surface-mount configurations

Standard diameters ranging from 0.3mm to 3.0mm to accommodate diverse application requirements

Custom plating patterns and selective finishing for cost optimization

Performance Reliability

Consistent electrical characteristics with low and stable contact resistance

Mechanical strength sufficient to withstand insertion forces and operational stresses

Thermal stability across operating temperatures from -55°C to +125°C

Plating adhesion that withstands thermal cycling and mechanical stress

Enhanced System Reliability

Precision manufacturing ensures consistent pin dimensions and plating quality, eliminating connection variability that can compromise system performance. The optimized material selection provides excellent conductivity while maintaining mechanical integrity under stress, reducing the risk of connection failures in critical applications.

Simplified Manufacturing Integration

The consistent dimensional characteristics of YFS PrecisionPin components facilitate automated assembly processes, improving production yields and reducing manufacturing costs. The pins' predictable insertion forces and reliable soldering characteristics minimize production variability, enabling higher throughput with fewer quality issues.

Design Flexibility and Customization

With multiple standard configurations and comprehensive customization capabilities, engineers can specify pins that precisely match their application requirements without compromising performance. This flexibility supports innovative designs while maintaining compatibility with existing manufacturing processes and equipment.

Cost-Effective Performance Optimization

By offering various plating options and material grades, YFS enables customers to select the optimal balance between performance requirements and cost considerations. The consistent quality reduces rework and warranty claims, delivering long-term cost savings through improved reliability.

Comprehensive Technical Support

Beyond component supply, YFS provides application engineering support, design recommendations, and prototyping assistance to ensure successful integration of PrecisionPin solutions into customer products.

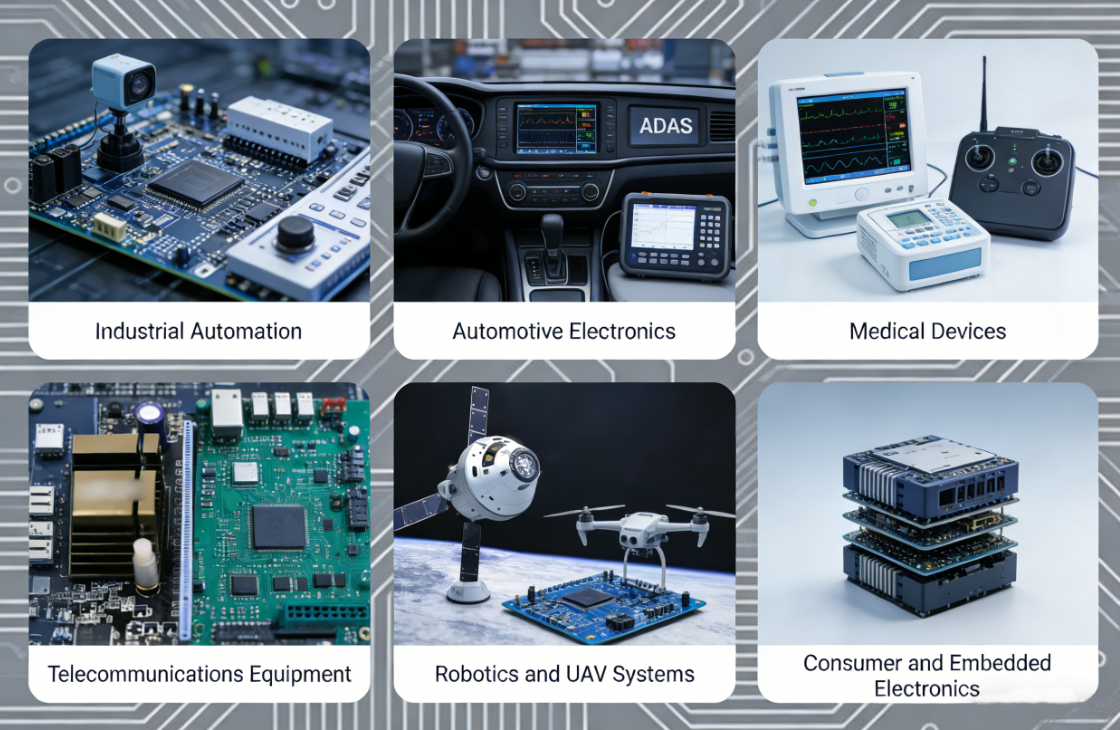

Consumer Electronics Manufacturing

Smartphone and tablet internal connections

Laptop and desktop computer component interfaces

Home appliance control board interconnections

Audio/video equipment signal and power connections

Industrial Control Systems

PLC and automation equipment backplane connections

Motor control and power distribution interfaces

Sensor and actuator wiring terminations

Industrial computing and communication equipment

Telecommunications Infrastructure

Network equipment board-to-board connections

Base station component interfaces

Data center server and storage connections

Fiber optic equipment electrical interfaces

Automotive Electronics

Engine control unit component mounting

Infotainment system board interconnections

Sensor and lighting system connections

Power distribution and charging systems

Medical Device Manufacturing

Diagnostic equipment internal connections

Patient monitoring system interfaces

Portable medical device component mounting

Surgical equipment electrical connections

Power Electronics Systems

Power supply component connections

Inverter and converter module interfaces

Renewable energy system connections

Battery management system interconnections

Q: What are the key considerations when selecting pin plating?

A: Pin plating selection depends on multiple factors including: application environment (corrosive conditions require gold or nickel), mating frequency (frequent mating benefits from hard gold), current requirements (higher currents may require thicker plating or different materials), soldering process compatibility, and cost considerations. Our technical team can provide specific recommendations based on your application parameters.

Q: How do press-fit pins differ from solder-tail pins?

A: Press-fit pins feature compliant sections that create an interference fit with the PCB hole, eliminating solder requirements and providing excellent thermal and mechanical characteristics. Solder-tail pins require soldering but offer simpler installation and lower initial tooling costs. The choice depends on production volume, reliability requirements, thermal management needs, and existing manufacturing processes.

Q: What quality assurance measures are implemented?

A: YFS employs comprehensive quality control including: dimensional verification using optical measurement systems, plating thickness testing with X-ray fluorescence, mechanical property validation, sample lot testing for electrical characteristics, and traceability systems for material lots and production batches. We maintain ISO 9001 certification with industry-specific quality protocols.

Q: Can custom pin designs be developed?

A: Yes, we offer extensive customization capabilities including: non-standard diameters and lengths, specialized head shapes, custom plating patterns, unique material compositions, and application-specific mechanical features. Custom development typically follows a structured process of requirements definition, prototype development, testing validation, and production ramp-up.

Q: How does pin straightness affect assembly and performance?

A: Pin straightness directly impacts insertion success rates, mating reliability, and mechanical stress distribution. Excessive deviation can cause insertion failures, damaged connectors, or uneven contact pressure. YFS maintains strict straightness tolerances to ensure reliable automated assembly and consistent long-term performance.

Q: What packaging options are available?

A: We offer multiple packaging solutions including: bulk packaging for manual assembly, tape-and-reel for automated SMT processes, tube packaging for specific insertion equipment, and custom packaging for unique production requirements. Packaging is designed to protect pins during shipping and handling while facilitating efficient production flow.

Q: How are pins protected against corrosion during storage?

A: We employ multiple protective measures including: controlled atmosphere storage, anti-tarnish treatments on sensitive platings, proper packaging materials that inhibit corrosion, and inventory management systems that ensure proper stock rotation. For extended storage, we recommend specific environmental controls and periodic inspection.

Q: What technical documentation is provided?

A: Comprehensive documentation includes: detailed dimensional drawings, material specifications, plating certification, mechanical property data, recommended PCB hole sizes, insertion force guidelines, soldering recommendations, and application notes for specific use cases. All documentation is available digitally and can be integrated into customer design systems.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.