interconnection pins represent the fundamental building blocks of electronic connectivity, serving as the essential interface components that establish reliable electrical pathways within countless electronic systems. YFS Technology (SZ) Co., Ltd. introduces PinConnect Precision Interconnection Pins, engineered to deliver uncompromising performance as standalone components or integrated elements within larger connector systems. These pins are meticulously designed to address the critical requirements of modern electronics manufacturing, where even the smallest component can significantly impact overall system reliability, assembly efficiency, and long-term performance.

PinConnect pins are manufactured through advanced precision engineering processes that ensure dimensional consistency, optimal electrical characteristics, and mechanical durability. As the demand for miniaturization continues to accelerate across industries, the importance of precision interconnection components has never been greater. These pins serve as the foundational elements that enable reliable connections in applications ranging from consumer electronics to industrial automation, telecommunications infrastructure, and medical devices. YFS Technology recognizes that successful electronic designs depend not only on sophisticated integrated circuits and complex PCB layouts, but equally on the quality and reliability of the basic interconnection components that bring these systems together.

Our PinConnect series represents a comprehensive solution for engineers and manufacturers seeking to optimize their connection interfaces. By focusing on the core component that establishes the electrical and mechanical interface between connected elements, we provide a critical enabling technology that supports the development of more reliable, efficient, and cost-effective electronic systems across all market segments.

The PinConnect series incorporates multiple design features that ensure optimal performance across diverse application requirements:

Precision Manufacturing: Each pin is manufactured to exacting dimensional tolerances using advanced forming and machining processes. This ensures consistent performance, reliable mating, and simplified assembly integration across high-volume production runs.

Material Excellence: Constructed from high-performance copper alloys with carefully selected plating options including gold over nickel, tin, and selective gold plating. These material choices optimize conductivity, corrosion resistance, and durability for specific application environments.

Versatile Configuration Options: Available in various styles including straight pins, right-angle configurations, press-fit designs, and solder-tail options. Multiple head styles, shoulder designs, and termination options provide flexibility for different assembly requirements.

Reliable Contact Design: Engineered contact geometry ensures consistent electrical performance with low and stable contact resistance. Optimized spring characteristics in compliant pin designs provide reliable mechanical retention while minimizing insertion force.

Environmental Durability: Designed to withstand challenging operating conditions including temperature extremes, mechanical stress, and corrosive environments. Plating systems are specifically formulated to maintain performance throughout the product lifecycle.

Implementing YFS PinConnect pins delivers significant benefits throughout the product development and manufacturing process:

Enhanced System Reliability: Precision manufacturing and optimal material selection directly contribute to improved connection reliability, reducing field failures and warranty claims associated with interconnection issues.

Simplified Assembly Integration: Consistent dimensional characteristics and engineered insertion/withdrawal forces streamline manufacturing processes, reducing assembly time and improving production yields.

Design Flexibility: Multiple configuration options allow engineers to select the optimal pin style for specific application requirements without compromising performance or increasing design complexity.

Cost Optimization: The combination of reliable performance, simplified assembly, and reduced field failures delivers significant total cost savings throughout the product lifecycle compared to lower-quality alternatives.

Technical Support: Comprehensive technical documentation including dimensional drawings, material specifications, and application guidelines supports efficient design integration and validation.

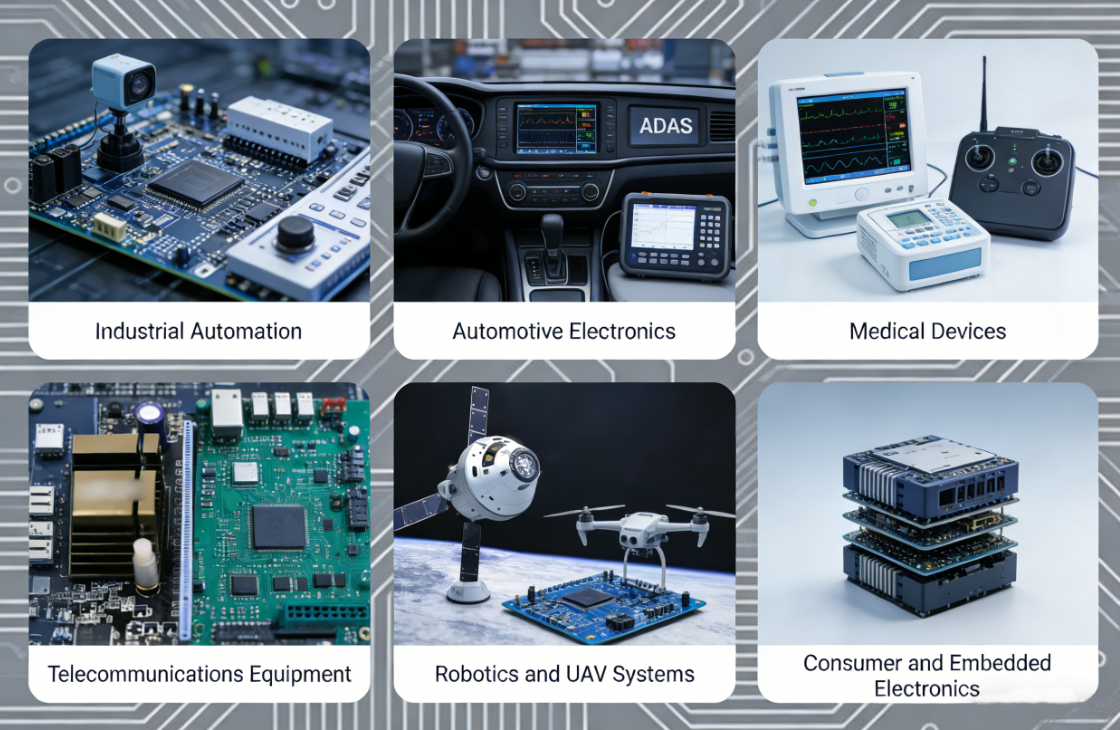

PinConnect precision pins serve essential functions across virtually all electronic market segments:

Consumer Electronics: Provides reliable interconnection in smartphones, tablets, laptops, home appliances, and entertainment systems where space constraints and cost considerations are balanced with performance requirements.

Industrial Automation: Serves as critical components in PLC systems, motor controllers, sensor interfaces, and industrial computing equipment where reliability under harsh operating conditions is essential.

Telecommunications Infrastructure: Enables reliable connections in base station equipment, network switches, routers, and transmission systems where long-term performance stability is critical.

Medical Devices: Used in diagnostic equipment, patient monitoring systems, and therapeutic devices where connection reliability directly impacts patient safety and system performance.

Automotive Electronics: Provides essential interconnection in engine control units, infotainment systems, sensors, and lighting controls where vibration resistance and temperature stability are paramount.

Power Electronics: Serves in power supplies, converters, inverters, and distribution systems where current carrying capacity and thermal performance are key considerations.

Test and Measurement Equipment: Provides precision interconnection in oscilloscopes, analyzers, signal generators, and other instrumentation where signal integrity and connection reliability are critical.

Q: What plating options are available for PinConnect pins?

A: We offer multiple plating configurations including gold over nickel (with various gold thickness options), tin plating, selective gold plating, and other specialized finishes. The optimal plating choice depends on your specific application requirements including environmental conditions, mating cycle requirements, and cost considerations.

Q: How do I select between straight pins and right-angle configurations?

A: The choice depends on your PCB layout and assembly requirements. Straight pins are typically used for vertical connections or press-fit applications, while right-angle configurations optimize horizontal board-to-board or board-to-cable connections. Our technical team can provide specific recommendations based on your mechanical design constraints.

Q: What is the difference between compliant pins and solid pins?

A: Compliant pins feature engineered spring characteristics that provide mechanical retention without requiring soldering, making them ideal for press-fit applications. Solid pins are designed for soldered connections and typically offer higher current carrying capacity. The choice depends on your assembly process and performance requirements.

Q: Can PinConnect pins be customized for specific applications?

A: Yes, we offer comprehensive customization services including special lengths, diameters, head styles, plating specifications, and packaging requirements. Custom designs typically require minimum order quantities and development timelines based on the specific requirements.

Q: What quality assurance processes are implemented for PinConnect production?

A: Our manufacturing processes include statistical process control, dimensional verification, plating thickness measurement, and functional testing. We maintain ISO 9001 quality management certification and can provide material certifications and test reports upon request.

Q: How do PinConnect pins compare to competitive products in terms of performance?

A: PinConnect pins are engineered to exceed industry standards for dimensional accuracy, plating quality, and mechanical durability. Independent testing has demonstrated superior performance in insertion/withdrawal force consistency, contact resistance stability, and environmental durability compared to standard commercial alternatives.

Q: What technical documentation is available to support design integration?

A: We provide comprehensive documentation including 2D dimensional drawings, 3D CAD models, material specifications, application notes, and assembly guidelines. This documentation is available through our technical support team and online resources.

Q: Are samples available for evaluation and testing?

A: Yes, evaluation samples of standard PinConnect configurations are available for qualified customers. For custom designs, we typically provide engineering samples once the design specifications have been finalized and approved.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.