duribility:10,000 cycles

Rated Current:20A-120A

Temperature Rise:30K maximum.

BTB connecting distance:H±0.50mm(customizable)

The Board-to-Board Connector System from YFS Technology is a precision interconnect solution engineered for reliable PCB-to-PCB connections within modern electronic devices. As devices trend toward miniaturization and higher functional integration, traditional soldered connections and standard connectors often fail to meet demands for high-density layouts, high-frequency signal transmission, and reliability in demanding environments. Our connector system offers pitch options ranging from 0.35mm to 2.00mm and supports various mounting configurations—including vertical, coplanar, and stacked—maximizing signal transmission within constrained spaces.

This connector system is built on a modular design philosophy, serving not merely as a component but as a complete PCB interconnection architecture solution. We provide end-to-end technical support, from connector selection and layout optimization to signal integrity analysis, helping customers address the combined challenges of high-speed data transfer, power distribution, and mechanical stability between PCBs. Whether for consumer electronics miniaturization or industrial equipment requiring high reliability, our solutions deliver precisely matched pathways to success.

1. Precision Engineered Construction

Utilizes high-precision stamping and molding processes with tolerances controlled within ±0.03mm

Dual-contact design ensures connection stability, with a mating cycle life exceeding 10,000 cycles

Polarization keys and fool-proofing features prevent mis-mating and improve assembly efficiency

2. Optimized Electrical Performance

Supports high-speed data transmission up to 20 Gbps, meeting interface standards such as USB4 and PCIe Gen4

Power contacts capable of carrying up to 15A, suitable for high-power applications

Impedance matching optimization reduces signal reflection and crosstalk

3. Environmental Resilience

Operating temperature range: -55°C to +125°C

Dust and water resistance up to IP68 (specific models)

Resistant to vibration (50G) and shock (100G), suitable for harsh industrial environments

4. Installation Flexibility

Available in Surface Mount Technology (SMT) and Through-Hole Reflow (THR) terminations

Supports various board-to-board stacking heights from 3mm to 25mm

Optional latching mechanisms ensure mechanical connection integrity

Integrated Technical Expertise

Our board-to-board connectors are more than mere components; they are system solutions integrating mechanical, electrical, and thermal management functions. Through Finite Element Analysis (FEA), we optimize stress distribution; via electromagnetic simulation, we enhance signal integrity; and with thermal simulation, we improve heat dissipation paths. This ensures optimal performance throughout the product's lifecycle.

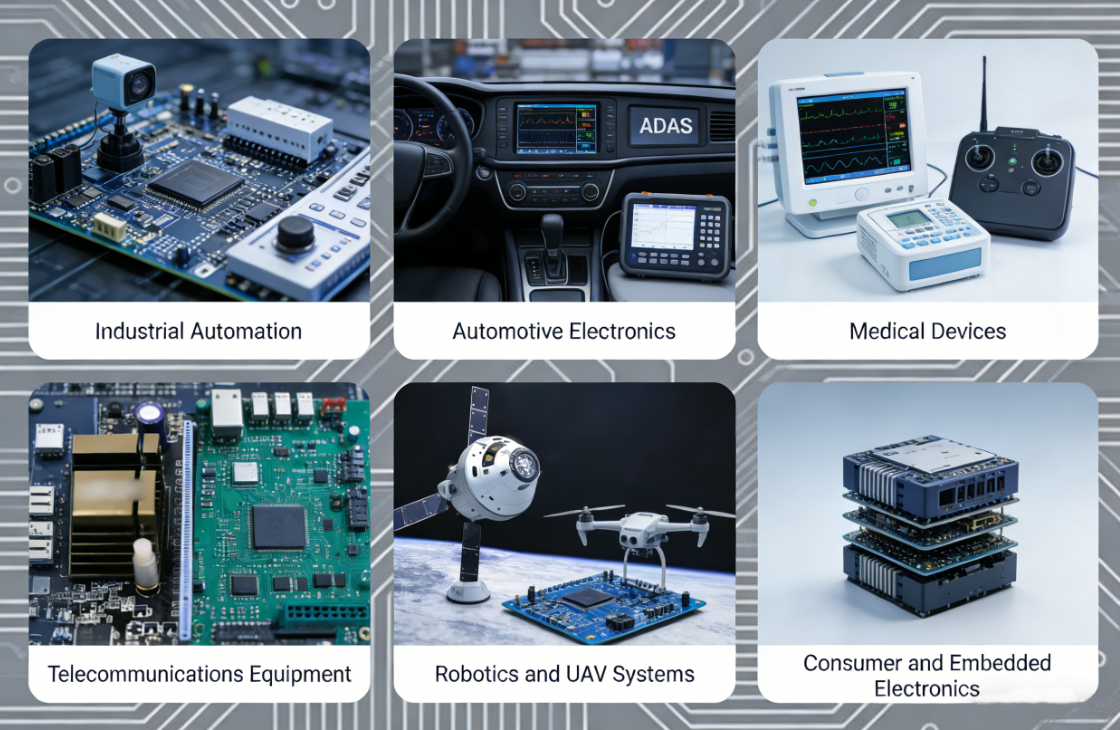

Application-Specific Adaptation

We offer customized variants tailored to industry-specific needs: medical versions use biocompatible materials with enhanced EMI shielding; automotive versions are AEC-Q200 certified with improved vibration resistance; industrial versions feature robust corrosion-resistant coatings and extended temperature ranges. This targeted approach allows customers to meet application requirements without over-engineering.

Full-Cycle Engineering Support

From PCB layout advice during the conceptual phase, to sample testing support during prototyping, and automated assembly solutions for mass production, we engage throughout the product development process. This end-to-end partnership reduces development timelines and mitigates system integration risks for our customers.

1. Communications Infrastructure

In 5G base stations and networking equipment, our connectors enable high-speed data links between baseband and radio units. The 0.8mm pitch series supports 28 Gbps transmission, meeting CPRI/eCPRI interface requirements, while its vibration-resistant design ensures long-term reliability in outdoor environments.

2. Medical Electronics

Portable medical devices such as patient monitors and diagnostic equipment utilize our 1.0mm pitch stacked connectors for reliable multi-board interconnection within limited space. Models feature antimicrobial coatings and comply with ISO 13485 quality management standards for medical devices.

3. Industrial Automation

Industrial controllers and machine vision systems employ our latching connectors to maintain secure connections under continuous vibration. The 2.0mm pitch series provides high-current transmission capacity for motor drives and power distribution needs.

4. Automotive Electronics

In-vehicle infotainment systems and ADAS controllers use our board-to-board connectors to link main processor boards with various functional modules. AEC-Q200 certified, they operate from -40°C to +105°C, with EMI-resistant designs ensuring signal integrity for critical data paths.

5. Consumer Electronics

Smartphones and tablets utilize our 0.35mm pitch micro-connectors for motherboard-to-subboard connections. Ultra-low profile designs (0.9mm height) meet slim form factor demands, while optimized gold plating ensures durability through repeated mating cycles.

Q1: How do I select the appropriate board-to-board connector pitch?

Pitch selection depends primarily on PCB layout density and signal requirements. 0.35-0.5mm pitches suit ultra-compact consumer electronics; 0.8-1.0mm pitches balance density with reliability for most industrial applications; 2.0mm and larger pitches provide greater mechanical strength and higher current capacity. Our engineers can provide specific recommendations based on your PCB design files.

Q2: What are critical considerations for high-speed signal transmission?

High-speed applications require attention to impedance matching, crosstalk control, and signal loss minimization. We offer connectors with integrated shielding structures and recommend complementary ground plane optimization. For applications above 10 Gbps, we suggest using differential pair configurations and models constructed with specialized high-speed materials.

Q3: How is connection consistency ensured during high-volume production?

We provide automated inspection equipment and assembly fixture solutions to ensure consistent mating precision. The connectors themselves feature guidance systems with audible/tactile feedback, allowing operators to positively confirm proper engagement. Additionally, we can supply soldering quality inspection criteria.

Q4: What special treatments are required for extreme environments (high temperature, high humidity)?

For high-temperature environments, we offer versions using High-Temperature Plastics (e.g., LCP) rated up to 150°C. High-humidity applications benefit from models with IP67 or higher ratings, supplemented by conformal coating protection. Applications in extreme environments require detailed consultation with our technical team during the selection phase.

Q5: What are the minimum order quantities and lead times?

Standard models have an MOQ of 1,000 pieces with lead times of 4-6 weeks. Custom variants require evaluation based on specific needs, with prototype lead times of 6-8 weeks and production lead times of 8-12 weeks. We maintain an expedited channel to provide rush services for strategic partners.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.