duribility:10,000 cycles

Rated Current:20A-120A

Temperature Rise:30K maximum.

BTB connecting distance:H±0.50mm(customizable)

YFS Technology's Board-to-Board Connectors represent the next generation of PCB interconnection systems designed for today's high-density, high-performance electronic devices. As electronic systems become increasingly compact while demanding greater functionality, reliable PCB-to-PCB connections have evolved from simple electrical bridges to critical system components affecting signal integrity, thermal management, and mechanical stability. Our connector solutions address the fundamental challenge of creating robust, high-fidelity connections between multiple printed circuit boards in constrained spaces.

Moving beyond basic pin-and-socket designs, our board-to-board solutions incorporate advanced materials, precision engineering, and innovative contact technologies to meet the demanding requirements of modern electronics across industries. From consumer wearables requiring ultra-low-profile connections to industrial control systems needing vibration-resistant interfaces, our product range provides optimized solutions for diverse application scenarios. We engineer these connectors not as standalone components but as integral parts of your system's architecture, considering electrical, mechanical, and environmental factors holistically.

Multi-Stack Configurations: Support for parallel, perpendicular, and coplanar board arrangements with stack heights ranging from 5mm to 20mm

High-Density Packaging: Pitch options from 0.4mm to 1.27mm, supporting up to 300 positions per connector

Mixed-Signal Capability: Dedicated contacts for power (up to 3A per contact), high-speed signals (data rates up to 16 Gbps), and low-noise analog signals

Enhanced Reliability: Gold-plated contacts (0.15-0.76μm) with optimized normal force for stable contact resistance

Robust Mechanical Design: Dual-beam contact systems, reinforced housings, and polarization features preventing mis-mating

Environmental Resilience: Operating temperature range from -55°C to +125°C, resistance to vibration (up to 20G) and mechanical shock

Space Optimization: Our connectors enable maximum functionality in minimum volume, with profile heights as low as 3.5mm and advanced shielding options that eliminate the need for additional EMI protection components. This allows designers to reduce overall system size by 15-25% compared to conventional interconnection methods.

Signal Integrity Preservation: Proprietary contact geometry and dielectric materials minimize insertion loss (< -1.5dB at 5GHz) and crosstalk (< -40dB at 5GHz). Our impedance-controlled designs maintain signal quality for high-speed digital interfaces including PCIe, USB 3.2, and LVDS applications without requiring signal conditioning components.

Manufacturing Efficiency: Featuring pick-and-place compatible packaging, solder inspection windows, and self-aligning mating interfaces that reduce assembly time by up to 40%. Our connectors support reflow soldering processes alongside traditional wave soldering, compatible with lead-free soldering temperatures up to 260°C.

Long-Term Reliability: Accelerated life testing confirms 5,000+ mating cycles without significant degradation in contact resistance. The mechanical design incorporates strain relief features that prevent PCB damage during mating/unmating operations, particularly important for field-serviceable equipment.

Design Flexibility: Modular systems allow mixing power, signal, and RF contacts within the same connector footprint. Custom configurations available with 8-week lead times for prototyping, supporting rapid product development cycles.

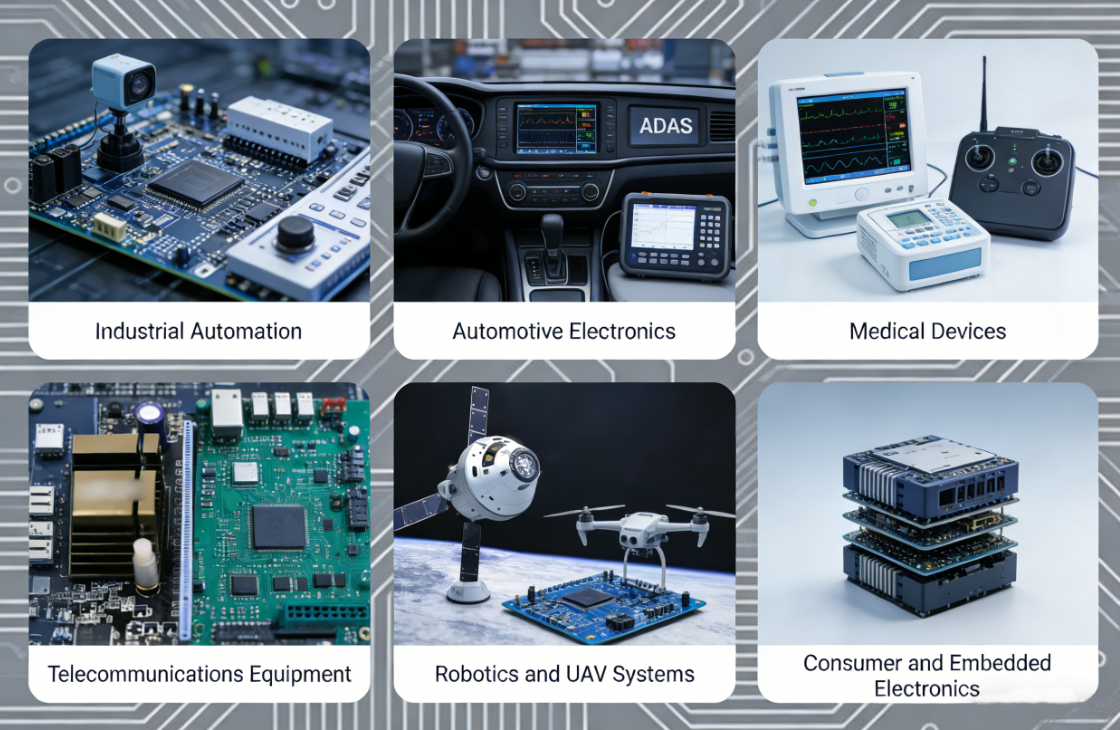

Telecommunications Infrastructure: 5G base station units, network switches, and optical transport equipment where multiple processor, memory, and interface boards require high-speed, low-latency interconnections. Our connectors support the 25G/100G Ethernet interfaces critical to modern networking gear.

Medical Diagnostic Systems: Portable ultrasound machines, patient monitors, and laboratory analyzers requiring reliable inter-board connections in environments with frequent movement, cleaning cycles, and electromagnetic interference constraints. Our medically-approved materials withstand sterilization processes.

Industrial Automation: PLCs, motor drives, and robotic control systems operating in environments with vibration, temperature fluctuations, and potential contamination. The connectors' robust construction maintains reliability in Category 3 industrial environments.

Consumer Electronics: High-end laptops, VR headsets, and premium audio equipment where slim form factors demand ultra-low-profile interconnections without compromising signal quality for displays, sensors, or high-fidelity audio components.

Automotive Electronics: Infotainment systems, ADAS controllers, and battery management systems meeting automotive-grade requirements for temperature cycling, vibration resistance, and long-term reliability over 15-year vehicle lifetimes.

Q: What design considerations are most important when selecting board-to-board connectors?

A: Four factors dominate selection: electrical requirements (current rating, signal speed, impedance control), mechanical constraints (available space, board orientation, mating/unmating frequency), environmental conditions (temperature range, vibration, potential contamination), and manufacturing considerations (soldering process, assembly automation, inspection requirements).

Q: How do your connectors address impedance matching for high-speed signals?

A: We employ controlled-impedance designs with precision dielectric materials (LCP or PCT) and optimized contact geometries. Our engineering team provides impedance models (S-parameters) for simulation integration, and we offer impedance testing reports with production batches to ensure consistency.

Q: What makes your connectors more reliable than competitive offerings?

A: Three key differentiators: our dual-point contact system provides redundant electrical paths, our contact plating process ensures uniform gold distribution without voids, and our housing materials maintain dimensional stability across the full temperature range. This combination results in lower and more stable contact resistance over the connector's lifetime.

Q: Can you support mixed technology requirements within a single connector?

A: Absolutely. Our modular platform allows combining power contacts (up to 5A), high-speed signal contacts (supporting protocols up to 16Gbps), and even coaxial or fiber optic contacts within unified mechanical housings. This eliminates multiple connector types and simplifies both design and assembly.

Q: What support do you provide during the design-in phase?

A: We offer comprehensive design support including 3D models (STEP files), electrical simulation models, thermal analysis data, and mounting force calculations. Our application engineers can review your PCB layout for optimal connector placement and routing recommendations. For volume applications, we provide test samples and prototyping kits.

Q: How do your connectors handle thermal management challenges?

A: Our power contacts feature thermal vias that conduct heat from the contact to the PCB ground plane, reducing temperature rise by 15-20% compared to standard designs. For high-current applications, we offer connectors with integrated heat sink attachment points or thermal interface materials.

Q: What quality certifications do your manufacturing processes hold?

A: Our connector production facilities are certified to IATF 16949 for automotive applications, ISO 13485 for medical devices, and AS9100 for aerospace applications. All production follows APQP processes with comprehensive traceability from raw materials to finished goods.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.