Product Name: Socket & Pin

Application for New Energy Electric Vehicles Connectors:

European standard IEC 62196-1/2/3, American standard J1772, Chinese standard GB 20234.1/2/3

Full set of charging connectors using sockets:

American standard J1772 uses pins. Sockets: 1.58mm; 2.8mm; 3.6mm European standard IEC 62196-1/2/3 uses pins and sockets: 3mm; 6mm

The national standard GB20234.1/2/3 uses pins and sockets: 3mm; 6mm

Electroplating specification: Silver plating

Materials: Brass, T2 copper Customized electroplating specifications and materials can be provided according to customer requirements.

In addition, we have a complete set of connector industry sockets:

1.5/3/5.7/6/8/9.07/10/12/14/15/16/18/20/22mm - 28mm

We can customize the specific current rating according to customer requirements.

Our company also has spring components for shielding purposes, which facilitate quick shielding of the interface.

Specifications: 35mm2, 50mm2, 75mm2, 90mm2, etc.

They can be customized according to the individualized needs of customers.

The Industrial-Grade PCB Pin Header Connector is a widely used interconnection component designed to establish stable electrical interfaces between printed circuit boards or between a PCB and external electronic modules. As a core element in many electronic assemblies, pin headers play a crucial role in ensuring reliable signal transmission, power delivery, and mechanical alignment.

At YFS Technology (SZ) Co., Ltd, pin header connectors are developed from a connector-solution perspective rather than as generic components. Each design focuses on contact reliability, soldering stability, and long-term performance consistency under real operating conditions. By optimizing pin structure, plating thickness, and insulating materials, our pin headers are suitable for both standard and demanding electronic environments.

This industrial-grade pin header connector is especially suitable for applications where stable mating, predictable electrical behavior, and compatibility with various PCB layouts are required. It supports efficient system integration while helping engineers maintain design flexibility.

The pins are precisely formed to ensure consistent solder joints and reliable electrical continuity, reducing the risk of cold soldering or intermittent contact.

Carefully designed pin length and cross-section improve mechanical strength while maintaining proper electrical conductivity.

The connector is available in different pin counts, row arrangements, and spacing options, allowing easy adaptation to diverse PCB designs.

Designed to meet common PCB assembly standards, the connector supports wave soldering and other conventional production processes.

The housing material provides electrical isolation and positional stability, helping maintain pin alignment during assembly and use.

Compared to temporary wiring or custom soldered connections, pin header connectors offer a standardized and reliable interface for system-level integration.

Material selection and surface treatment are optimized to maintain electrical and mechanical performance over extended operating periods.

Pin headers allow easy connection of daughter boards, adapters, or peripheral modules, supporting scalable and upgrade-friendly designs.

Standardized pin layouts help shorten design cycles and reduce errors during PCB assembly.

Beyond manufacturing, YFS Technology assists customers in selecting suitable pin header configurations based on electrical load, layout constraints, and application scenarios.

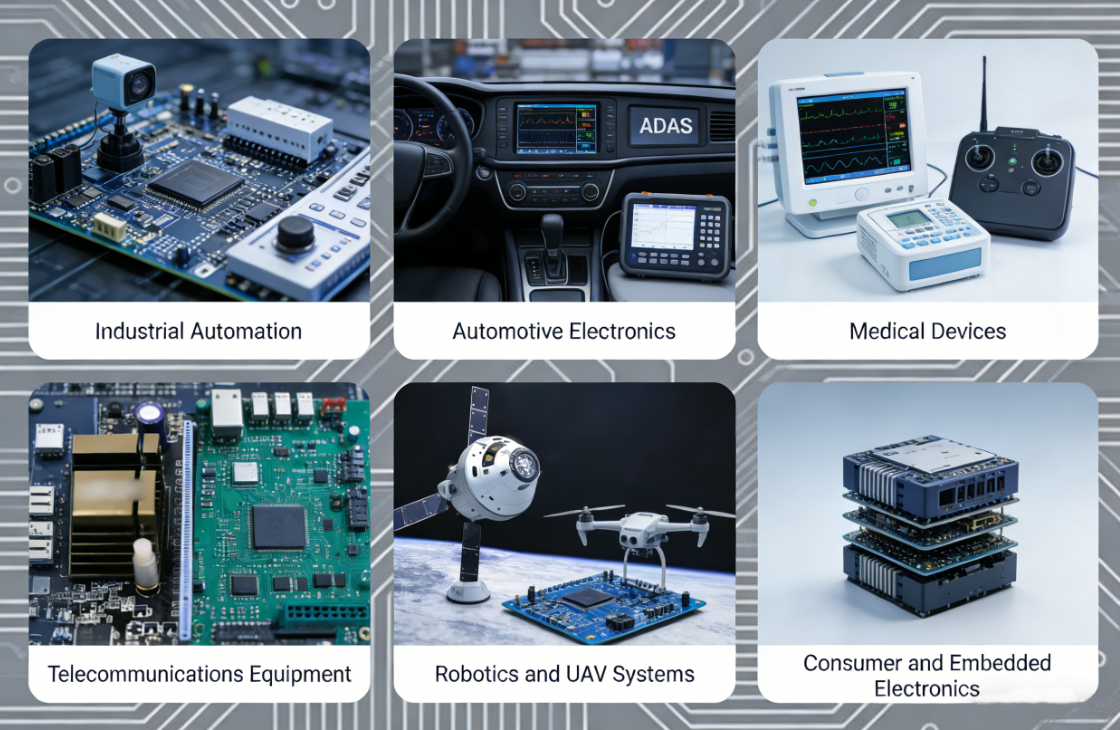

Industrial-Grade PCB Pin Header Connectors are commonly used in the following fields:

Industrial control and monitoring systems

Communication terminals and interface boards

Embedded controllers and evaluation boards

Consumer electronic products

Medical electronic devices

Automotive electronic subassemblies

Robotics and automation equipment

Power distribution and control circuits

Q1: What is the primary function of a PCB pin header connector?

A: It provides a standardized and reliable electrical interface for connecting PCBs or modules for signal and power transmission.

Q2: Can this pin header be used in industrial environments?

A: Yes. It is designed for stable performance in industrial electronic systems requiring reliable connections.

Q3: Is this connector compatible with automated PCB assembly?

A: Yes. The pin header is compatible with standard PCB manufacturing and automated assembly processes.

Q4: Does pin header spacing affect performance?

A: Proper spacing helps ensure signal integrity and mechanical stability, which is why multiple spacing options are available.

Q5: Can YFS Technology customize pin header connectors?

A: Yes. Customization options include pin count, length, arrangement, and housing specifications.

Address:Shenzhen City, China

Mobile Phone:+86 17656553585

Email:davykou0@gmail.com

© 2025 YFS Technology (SZ)Co., Ltd All rights reserved.

This website uses cookies to ensure you get the best experience on our website.